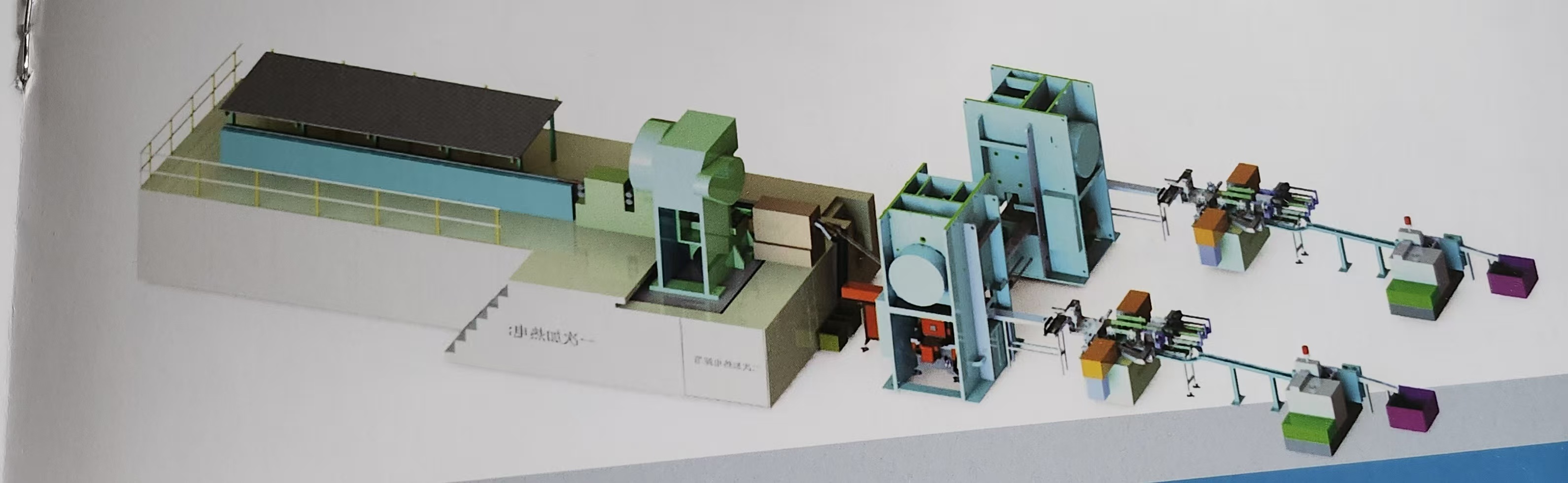

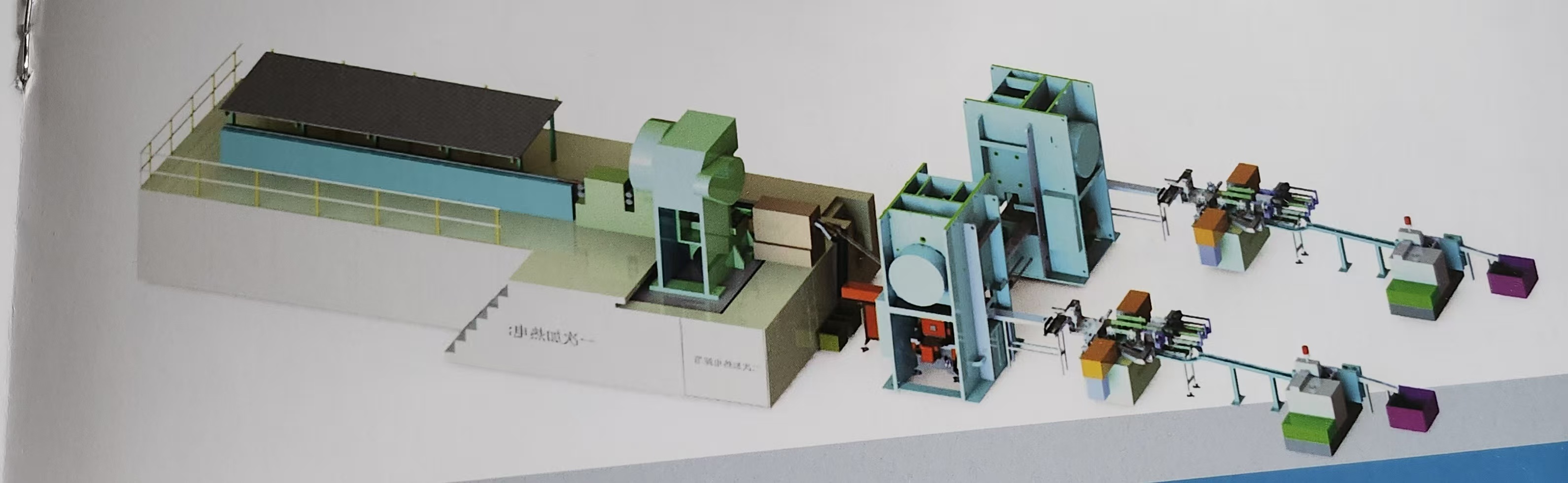

The process of the automated forging robot production line for bearings

The process of the automated forging robot production line for bearings includes the following steps:

Preparation of raw materials: Select suitable

raw materials for forging and ensure that their quality and size meet the requirements.

Adjustment and preparation of forging manipulator: The manipulator needs to be adjusted to a

suitable forging posture and preheated to increase lubrication.

Loading: Load the raw materials into the forging robot for positioning and fixation.

Forging process: The forging robot arm performs automated forging according to preset

forging programs and parameters, including high-temperature heating, pressure application, and cooling steps.

Cooling and unloading: After forging is completed, the robotic arm cools the forging and then unloads it.

Quality inspection: Conduct quality inspection on forgings, including dimensions, surface quality, and internal quality, to ensure that they meet the requirements.

Sorting and packaging: Classify forgings based on quality inspection results and pack and store them appropriately.

Recording and feedback of production data: Recording data during the production process, analyzing process parameters and equipment status, and providing a basis for further optimization. Through the application of automated forging robotic arms, the production of bearings can be more efficient, precise, and stable. During the operation, attention should be paid to following safety regulations to avoid accidents.

+86-769-38973158

+86-769-38973158 +86 13622624429

+86 13622624429 machinery_vk@21cn.com

machinery_vk@21cn.com +86-769-38973158

+86-769-38973158 +86 13622624429

+86 13622624429 machinery_vk@21cn.com

machinery_vk@21cn.com