+86-769-38973158

+86-769-38973158 +86 13622624429

+86 13622624429 machinery_vk@21cn.com

machinery_vk@21cn.com

+86-769-38973158

+86-769-38973158 +86 13622624429

+86 13622624429 machinery_vk@21cn.com

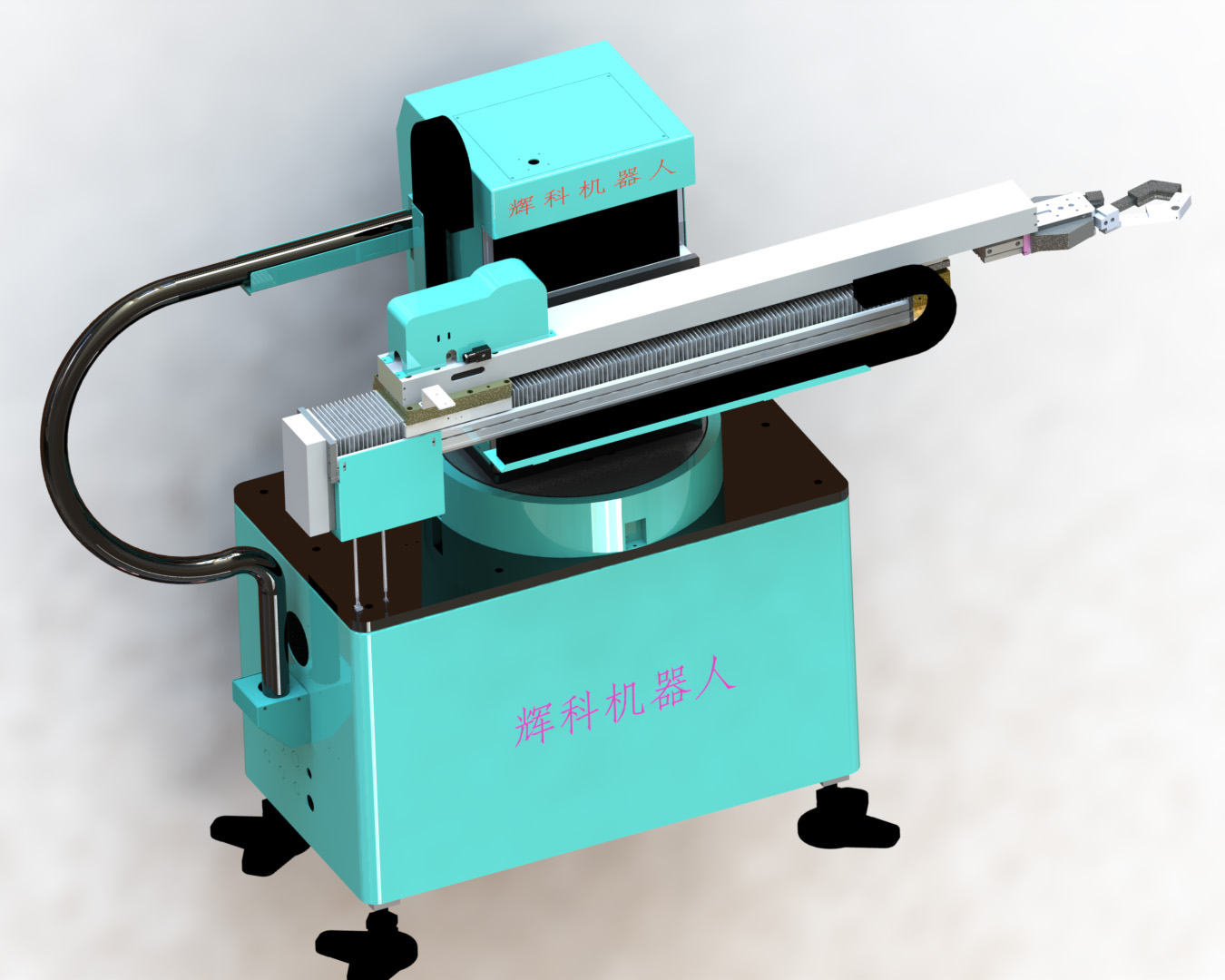

machinery_vk@21cn.comThe difference between special forging manipulators and general joint manipulators

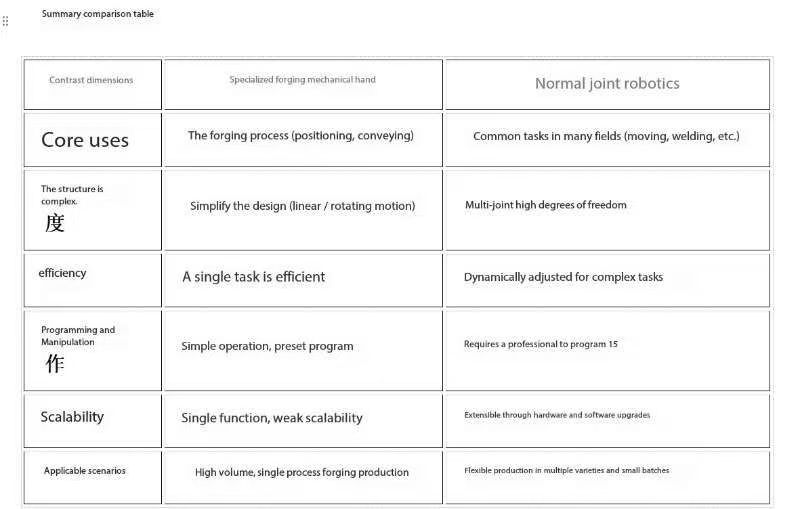

1. Structural Design and Degree of Freedom

·Specialized forging manipulator: usually adopts a simplified structure (such as cylindrical coordinate or rectangular coordinate type), and the movement forms are mainly linear and rotational. It is optimized for the forging process. For example, the swing arm forging manipulator emphasizes fast and stable repeated movements.

·Ordinary joint manipulator: It adopts a multi-joint humanoid arm structure (such as a six-axis joint design), which has a higher degree of freedom, can realize complex spatial trajectory movements, and can flexibly adapt to a variety of task scenarios (such as handling, welding, spraying, etc.).

2. Function and applicable scenarios

·Specialized forging manipulator: specially customized for forging processes, such as loading and unloading, station transfer, etc., emphasizing high load capacity, impact resistance and continuous operation stability, and suitable for harsh environments such as high temperature and high pressure.

·Ordinary joint manipulator: It has strong versatility and can complete tasks in multiple fields (such as assembly, inspection, flexible processing) through programming, but its adaptability to extreme working conditions is weak.

3. Efficiency and Precision

·Dedicated forging manipulator: The action path is fixed or preset, and the operation efficiency is high (for example, the swing arm forging manipulator can complete a single task faster than the joint robot), but the adjustment flexibility is low.

·Ordinary joint manipulator: supports dynamic programming to adjust the trajectory, with higher accuracy (such as micron-level positioning), but requires additional debugging time, suitable for small batch and multi-variety production.

. Programming and Operation Complexity

·Specialized forging manipulator: usually uses preset programs or simple interface operations (such as human-computer interaction to set parameters) to reduce the technical requirements for operators.

·Ordinary joint manipulator: It requires professionals to write complex programs, and the debugging cycle is long.

5. Cost and Scalability

·Dedicated forging manipulator: The initial investment is low, but its function is single and it is difficult to expand to other scenarios.

Ordinary joint manipulator: The initial cost is higher, but it can adapt to new needs through software upgrades or hardware expansion, and has stronger long-term reusability

It can be seen from the above comparison that there are significant differences between the two in terms of core design goals, functional focus and applicable scenarios. The choice needs to be based on actual production needs.